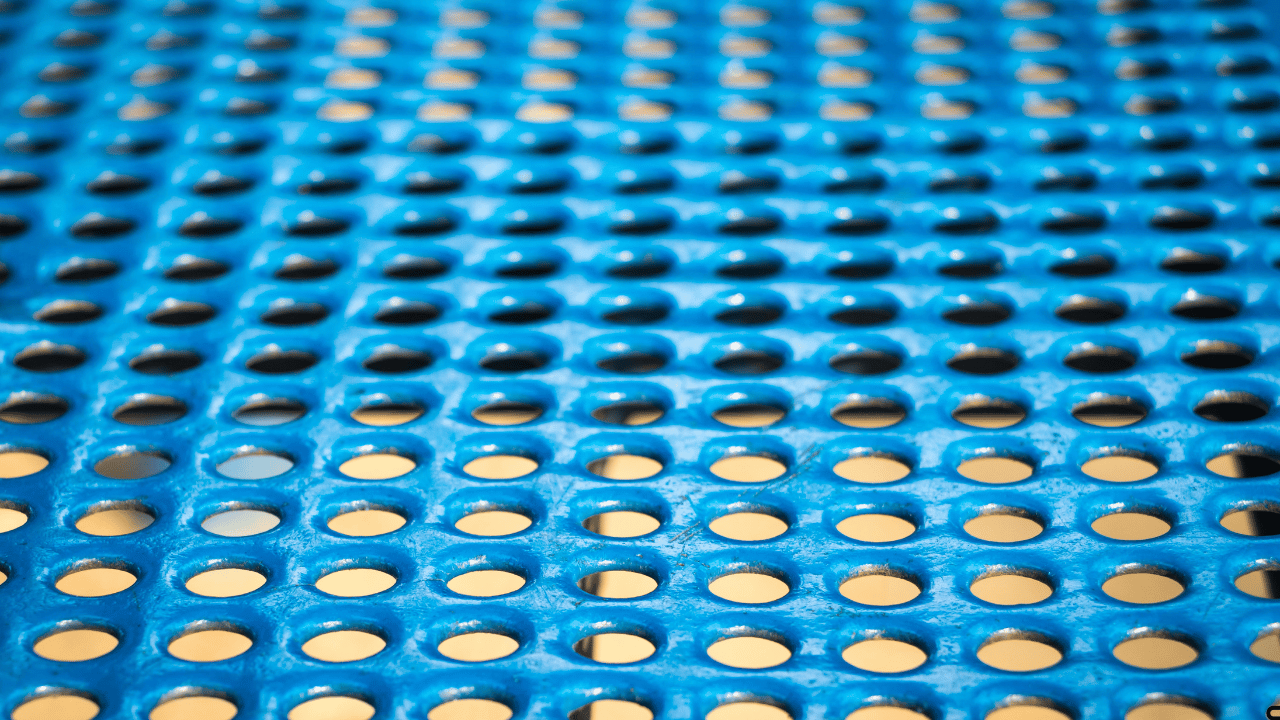

The Versatile Perforated Sheet

Perforated sheets or notched boards, often abbreviated as perf sheets or perf boards, are materials with small holes or perforations. The perforations enable one to easily part with the sheets or cut across the markings.

Perforations Make Shearing Simple

The primary use of perforations is to introduce stress points in the materials, which can be easily cut or delaminated. This is particularly helpful whenever you require making more sections on a single sheet of paper. It is, in fact, very efficient as it dictates where the separations should be made along the holes.

Some everyday items made using perforated sheets:

The pattern of holes allows air, water, and particles to flow through the material:

Filters

Percussion cloth is utilized for sowing and straining solid particles from the liquid streams in many fields. The large debris is stopped and retained by the perforated sheets while the fluids are allowed through.

Ventilation Panels

Perforated aluminum and steel sheets can create porosity and openwork structures that enable airflow. These panels have holes punched in the art that let air flow through them and are used for aesthetics in architecture. Perforated ventilation panels can be installed for mechanical purposes in rooms, heating, ventilation, air conditioning systems, noise barriers, and other structures.

Architectural Design

Perforated metal sheets are used in architectural projects for facades, sunshades, partitions, and decorative panels. They can provide visual interest and functionality, allowing light and airflow while maintaining privacy.

Furniture

Perforated metal sheets are utilized in furniture design for items like chairs, tables, shelving units, and cabinets. They can add a modern and industrial aesthetic and functionality, such as ventilation or cable management.

Screens and Room Dividers

In residential and commercial settings, perforated metal sheets are used as screens and room dividers. They can separate spaces while allowing light and air circulation, enhancing privacy without completely blocking views.

Filters and Strainers

Perforated metal sheets are used in various filtration applications, such as air filters, water filters, and oil strainers. The perforations can be customized to achieve specific filtration requirements.

Industrial Applications

Perforated metal sheets are extensively used in industrial settings for machinery guards, conveyor belt systems, ventilation panels, and acoustic panels. They provide strength and durability and often serve functional purposes such as noise reduction or airflow control.

Automotive

Perforated metal sheetsare used in automotive applications for grilles, radiator covers, interior trim panels, and speaker covers. They offer a combination of aesthetics and functionality in vehicle design.

Retail Displays

In retail environments, perforated metal sheets are used for display racks, shelving units, and decorative elements. They can be customized to fit branding aesthetics and provide durability in high-traffic areas.

Decorative Crafts

In addition to commercial and industrial uses, crafters can utilize perforated papers and films for decorative projects:

Stencils

Thick sheets can be used as template stencils for painting and crafting by drilling holes into them. The sheets are placed over the working surface while the paint is spread over the holes. If you lift it, you leave a pattern on the surface below, which was observed

in the experiment.

Streamers

Perforated sheets or plastic table covers in long accordion-folded strips of the same color as the event can also produce brightly colored event streamers. The holes are there for the ventilation to avoid the structure to sag and for the aesthetic values.

Difference Between Punched sheet and perforated sheet

Punching of metal sheets refers to the processes of creating holes through the metal sheets while perforated metal sheets refer to metal sheets with small holes.

Perforated metal and punched metal are two types of metal sheets that have a number of holes on them.

However, there are some critical differences between these two types of metal sheets:

Hole Shape

– Perforated metal sheet is a sheet in which there are round holes, and these holes are made by piercing the sheet using pins or needles. The holes are equally sized and shaped round holes on the sheet with no deviation from one point to the other.

– Holes of punched metal sheets can be of any size – round, square, rectangular, oblong’s etc and can be of any size because it is done with a mechanical punch press.

Hole Size Consistency

– Concavity of perforated metal sheets: When making holes in the metal sheets, the holes in the perforated metal sheets are uniform in size throughout the sheet because they are made using pins or needles of the same diameter.

– This could be due to the fact that punched metal sheet holes can be of a more significant variation in size, mainly if several shaped dies are employed to form various forms and patterns of the holes.

Hole Spacing

– In perforated sheets, the number of holes and their locations is set in such an organized pattern that distance between any two holes is equal.

– The Hole pattern or the design is generally such that punched sheets have variable hole spacing. The holes can be small and equally placed in some areas of the pattern but large and randomly placed in other areas.

Hole Density

– Perforated sheets are generally characterized by the presence of more holes compared to the space in the sheet (more hole concentration per square inch/foot).

– Punched sheets tend to have less number of holes as compared but it can vary depending on the size and arrangement of the holes.

Hole Edge Quality

– The cut edge is free from any sharpness around the holes in perforated sheets due to the fact that they are pierced cleanly with pins.

– A punched sheet is made of holes, which can have rougher and sharper edges caused by shearing action of punch dies.

Applications

– An exciting thing about perforated metals is that it has a wide use in areas such as screens, filters, guards and drains.

– Punched metal can be mainly applied aesthetically for making panels, partitions, signs, guards etc. Perforated metal is more favorable for a situation where more amount of flow area is required.

In conclusion, one can state that the primary distinction between the two lies in the fact that perforated metal includes small round and equidistant holes that are made by piercing, and punched metal, in turn, may contain decorative shapes of holes that are located non-uniformly and are made by the help of stamping with the use of dies. As for the hole features, perforated metal also generally has a higher hole density and more refined edges to the holes.

In any given industry or area of practice, perforated sheets are flexible since one can select a preferred perforation pattern. Specific application requirements can be tailored using variations in size and distribution pattern of holes. Intermediate materials are sheets that contain small round holes drilled through them, which resemble solid sheets as well as meshes.

With opening spaces and the segmentation of materials, they are considered one of the most flexible industrial supplies.